Preventative & Predictive Maintenance

Implement Advanced

Maintenance Strategies

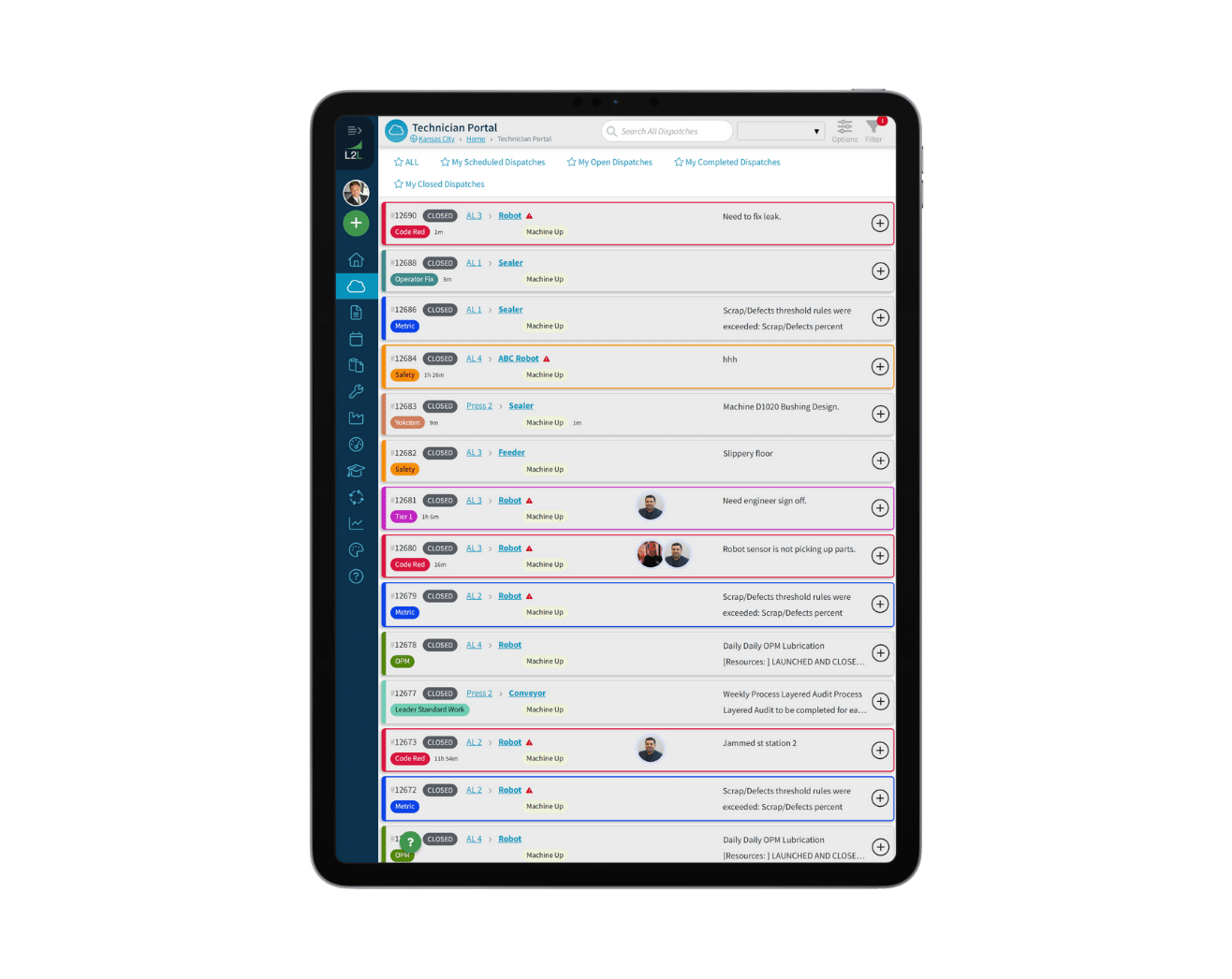

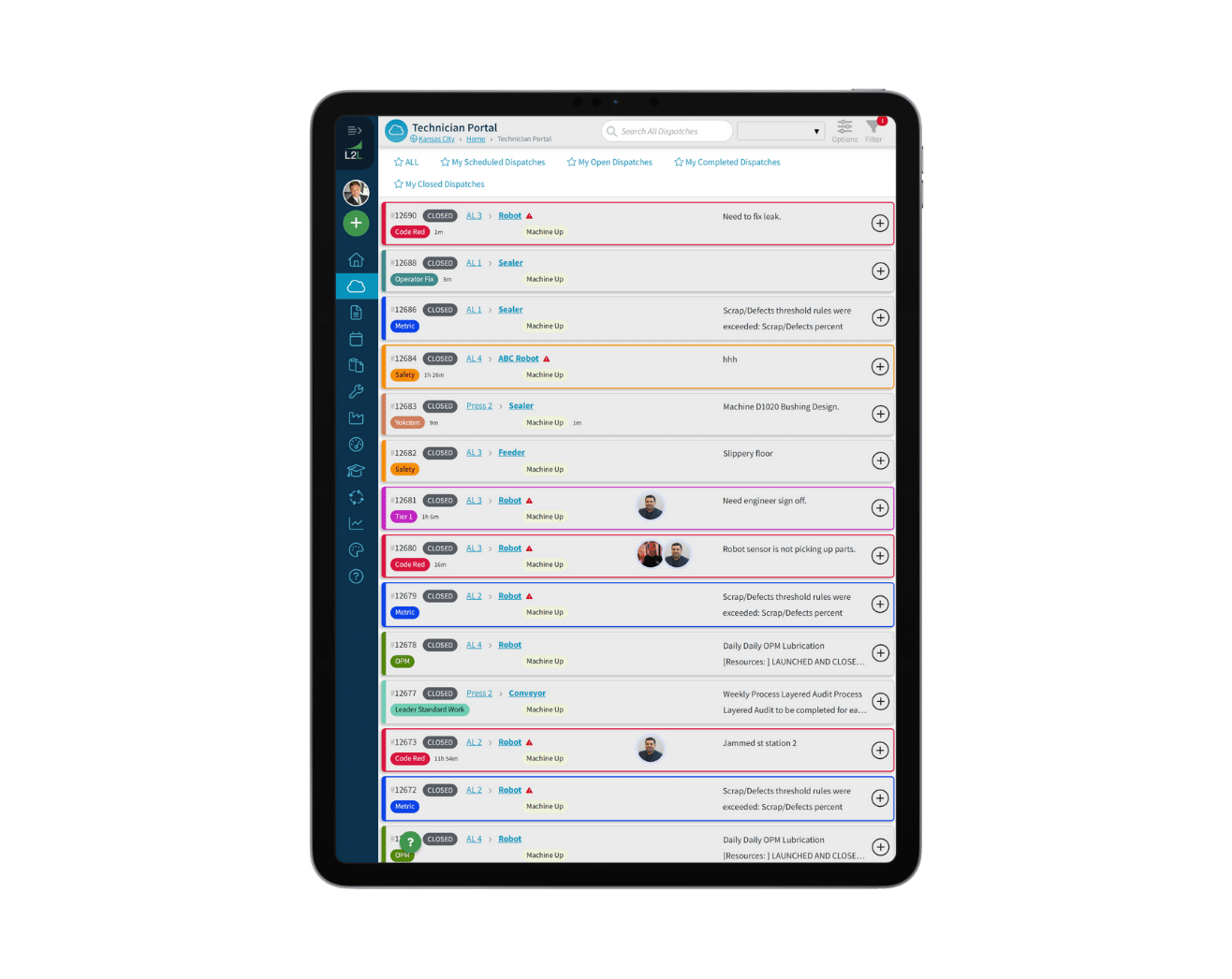

Technician Portal

The Technician Portal is a single screen interface that includes all the tools a technician needs to diagnose the problem, get the right parts, fix the machine, and document the fix.

Cycle- and Condition-Based Maintenance

Control workflow and escalations, alerting the right people and ensuring follow-through on critical maintenance tasks.

Create Manufacturing Flow

Integrate with L2L's Production module for increased visibility and coordination with manufacturing schedules, maximizing uptime and throughput.

Single-Screen Technician Portal

The new Technician Portal is an efficient, modern, and mobile interface that allows your maintenance technicians to quickly diagnose the problem, get the right parts, fix the machine, and document the fix.

REDUCE YOUR DOWNTIME

Built for Speed, Security, and Continuous Improvement

Download the Brochure

We Have Avoided Costly Unplanned Failures

"By responding to real time data, we have avoided costly unplanned catastrophic failures. Avoiding costly repairs and unplanned downtime is why we took on this project. So far, we're happy with L2L's results."

Jason Bryan

Change Your Shop Floor Culture

"The L2L data has helped Maintenance and Operations teams understand the importance of what they do. The culture is starting to change"

.png)