4 min read

L2L and Dart Container Recognized as Finalists for the 2024 Manufacturing Leadership Awards

The partnership provided double-digit improvements to Dart’s OEE and set the stage for a pilot facility to enjoy its...

June 18, 2018

Leading2Lean Announces 2018 Award Winners of Operational Excellence and Manufacturing Innovation

Autoliv and BorgWarner Plants Honored for Successful Deployment of Leading2Lean’s CloudDISPATCH Technology

Salt Lake City, Utah – June 18, 2018 –Leading2Lean, a cloud-based lean manufacturing solution provider, today announced the 2018 winners of its annual Operational Excellence (OpEx) Awards. The companies honored for outstanding operational performance were BorgWarner in Seneca, S.C., Autoliv in Ogden, Utah, and Autoliv Livbag in Brest, France. The awards recognize the impressive results each plant has achieved using Leading2Lean’s CloudDISPATCH technology. For all three plants, results included improved efficiency, reduced downtime, and increased profitability.

“Our Operational Excellence Awards recognize the operational success our customers have achieved by engaging and empowering their workforce using technology” said Keith Barr, President and CEO of Leading2Lean. “Autoliv and BorgWarner have created an impressive list of best practices in the use of our CloudDISPATCH software which is driving improvement in the task at the worker level. This in turn makes us a better, more responsive partner. We have found that close collaboration with our customers always creates the best outcomes for them, and us.”

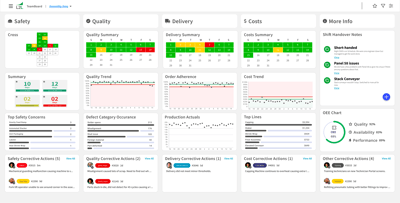

Leading2Lean’s CloudDISPATCH technology increases real-time visibility at all levels of a manufacturing company, especially on the plant floor. Using CloudDISPATCH, plant floor employees have the real-time data they need to innovate and solve costly production problems. The solution also establishes a higher level of transparency that is critical in engaging people on the floor. When people can see what their peers are doing, and what production issues may be happening, accountability to solve those issues increases. Transparency and empowerment creates a need for workers to analyze and make decisions faster. In these cases, technology isn’t replacing humans; it’s enhancing human performance.

Autoliv AOA, Ogden, UT

Autoliv, a global manufacturer of automotive safety systems, was an early adopter of CloudDISPATCH, and since implementing the solution at the Ogden, Utah AOA plant, has demonstrated continuous improvements in operational efficiency. Operations that previously were manual have now been successfully digitized and streamlined, increasing the accuracy and usefulness of production data.

Autoliv, Brest, FR

Autoliv’s Livbag facility in Brest, France, is another award winner for its impressive operational performance and innovation. One example of their success can be found in their spare parts management. Before CloudDISPATCH, the Livbag facility relied on spare parts being transported by workers across the plant floor. After installing CloudDISPATCH, Autoliv was able to successfully combine the system with automation to transport and deliver spare parts to the right locations at the right times. This eliminated the need for workers to perform this function, resulting in 352 labor minutes saved per shift, and the efforts of workers could now be focused on more value-added activities.

“This represents a substantial cost savings and improvement in efficiency,” said Barr. “I applaud both Autoliv Livbag’s and AOA’s progress and performance.”

BorgWarner, Seneca, SC

BorgWarner’s Seneca facility is the third recipient of the Operational Excellence Award. BorgWarner, an automotive propulsion system manufacturer, installed CloudDISPATCH for detection of malfunctioning equipment, maintenance monitoring, and planned machine work orders, overseeing the status of machines, data for operations reviews, and tracking KPIs. As a result of CloudDISPATCH, BorgWarner reported a 27% decrease in machine dispatch occurrences, a 57% decrease in production line issues, a 44% reduction in machine downtime minutes, all while achieving a 52% increase in output.

“These results showcase the impact that the BorgWarner team’s efforts and Leading2Lean’s technology can have when utilized to the fullest extent,” said Barr.

Leading2Lean offers its congratulations to all facility award winners. To be considered for next year’s Operational Excellence Awards, companies can enter plants at www.leading2lean.com/opex-awards/.

About Leading2Lean

Founded in 2010, Leading2Lean is focused on solutions for multinational manufacturers. Leading2Lean is focused on operational excellence and run by an executive team with extensive experience in manufacturing, engineering, and turning around failed enterprises. Its cloud-based systems provide critical real-time information to help rank-and-file workers do their jobs better and take ownership of their work. A better-focused and motivated workforce produces more and of better quality, and leads to habits of continuous improvement. For more information, visit leading2lean.com.

Apr 11, 2024by L2L

The partnership provided double-digit improvements to Dart’s OEE and set the stage for a pilot facility to enjoy its...

Feb 8, 2024by L2L

Kyle Petty to Keynote the Annual User Conference in May

SALT LAKE CITY, Utah, February 8, 2024 - L2L, the global...

Sep 6, 2023by Trent Johnson

Salt Lake City, UT – September 6, 2023: L2L, the Connected Workforce pioneer, is excited to announce the highly...

What makes L2L so unique is the fact that the product was developed by real manufacturing users. People that truly understand the day-to-day issues and concerns that drive the production floor.